FEA Simulation Services: Cut Prototyping Costs 73% | PPS

%article_excerpt%

Simulation Modeling Verification: Reduce Design Errors by 25%

Unverified simulations cause 25% more design errors and costly redesigns. Master simulation validation, verification, and interpretation to ensure trustworthy results.

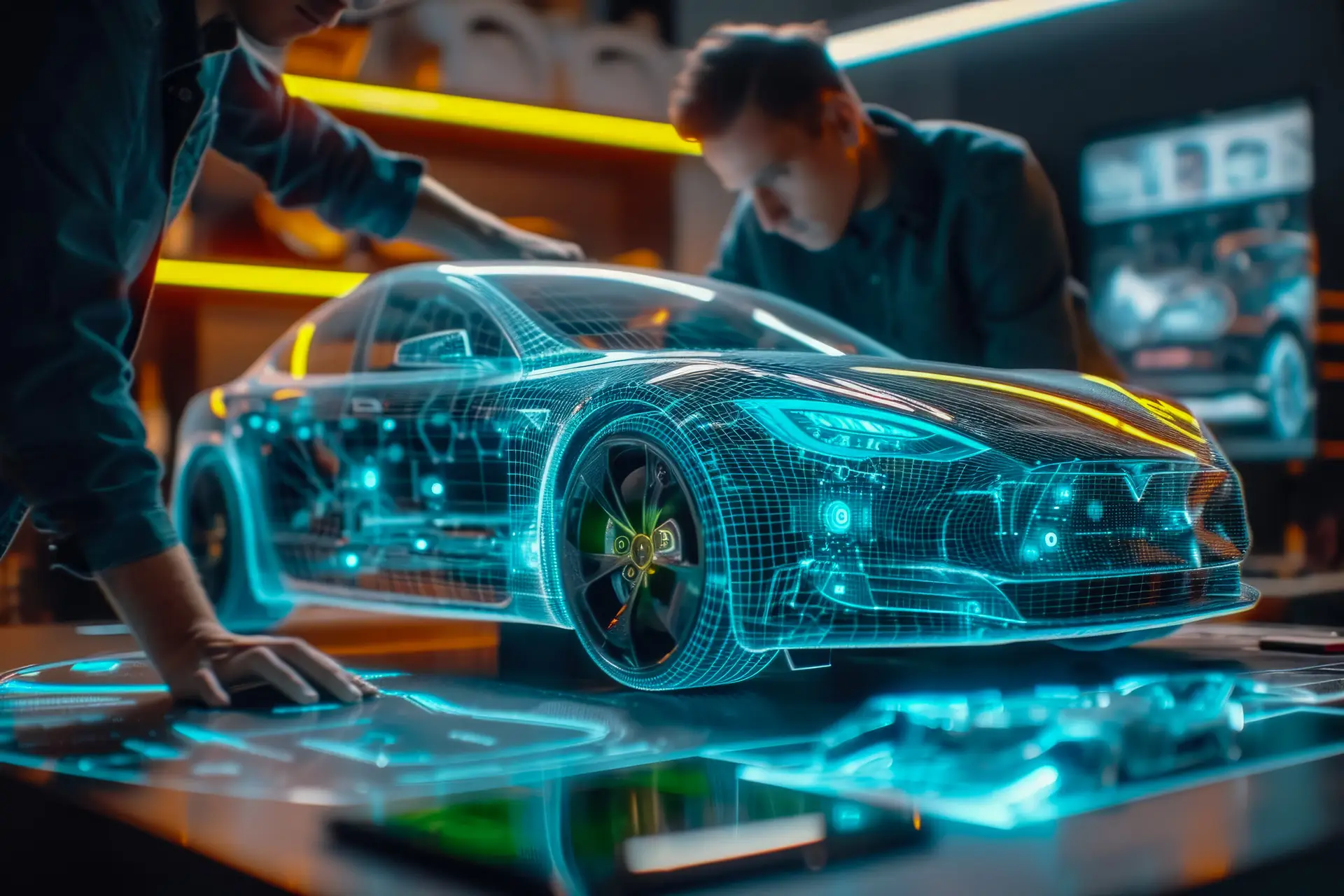

Product Development Services: 76% Cost Reduction via Simulation

Simulation-driven product development cuts prototyping costs by 76% and reduces time-to-market by 75%. Improve quality to 90% with CFD and FEA analysis services.

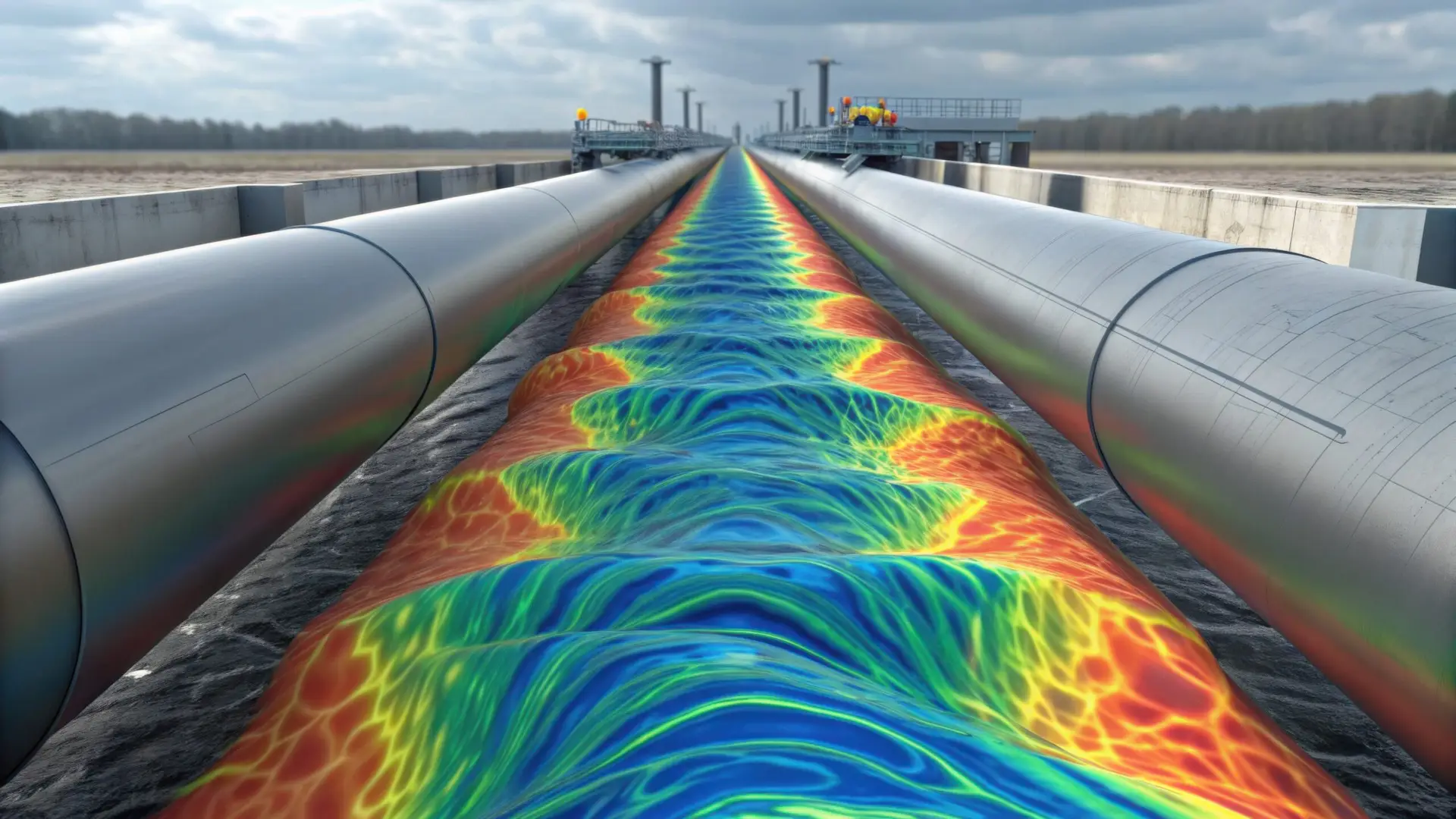

Master Turbulence in CFD: Models & Insights

Explore turbulence modeling fundamentals in CFD, from Navier-Stokes equations to k-ε variants, and discover practical guidelines for accurate simulations in fluid mechanics and engineering.

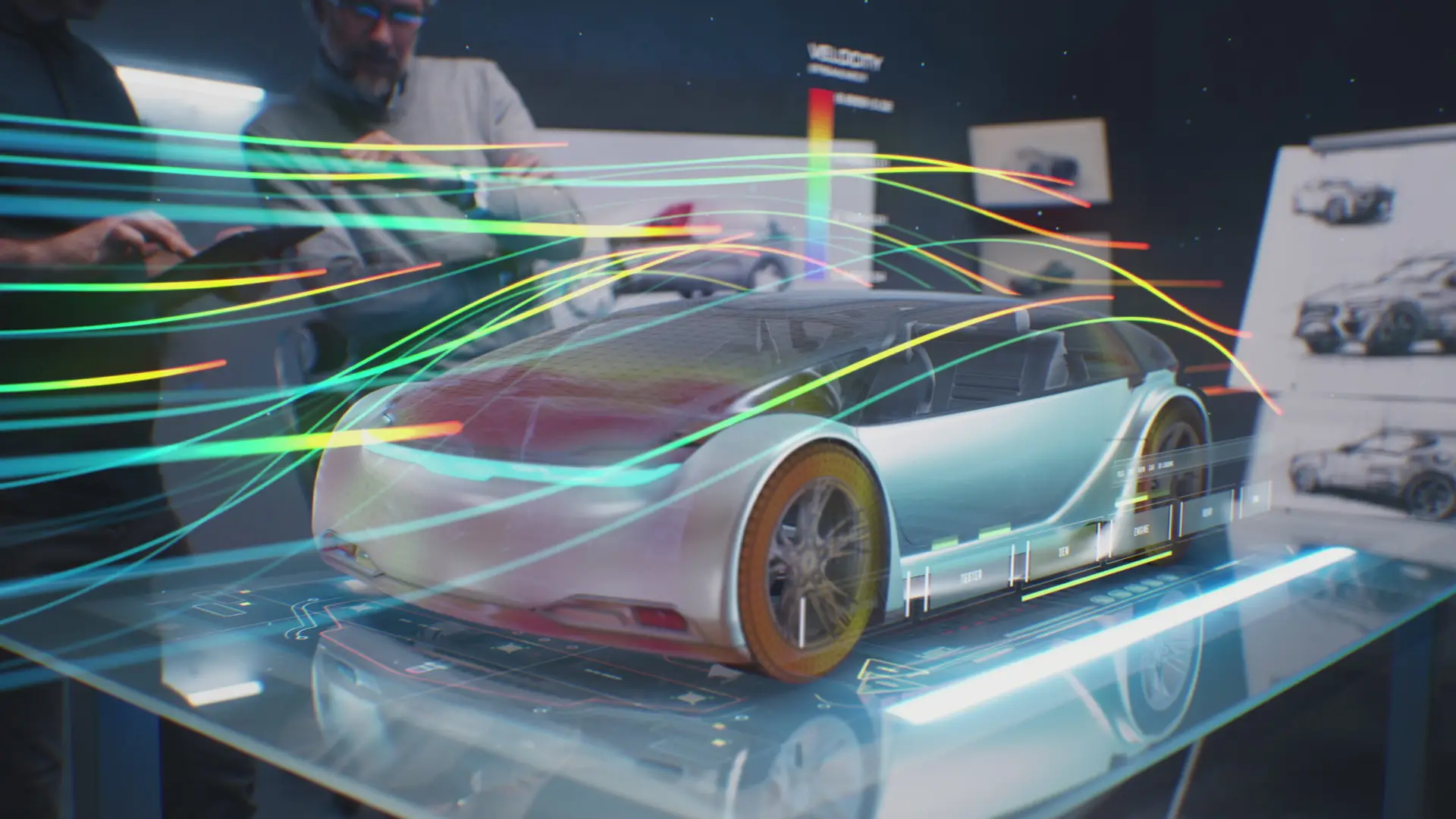

Why Simulation Software is Essential in Design

Explore why simulation software is key in mechanical engineering design. Learn how FEA and CFD reduce prototypes, shorten cycles, and enable data-driven decisions for optimized product development and innovation.

Why Simulation is Essential in Engineering – Part 2

In Part 2, delve into why FEA and CFD simulation are crucial for engineering design. See how they resolve key queries, foster innovation, lower costs, and refine manufacturing using tools like ANSYS nonlinear analysis and computational fluid dynamics.

Master Distortion Energy: Cut Failures 25% in FEA

Struggling with unpredictable ductile failures in mechanical engineering designs? Overlooked distortions cause costly delays and collapses, eroding your edge in automotive and aerospace—failure rates soar 25% without robust analysis. Enter distortion energy theory (von Mises yield criterion): a game-changer for failure analysis, predicting yielding via shape-changing strains and simplifying multi-axial tests. PPS empowers CAE engineers with ANSYS nonlinear analysis and prediction software to master heat flow, thermal mechanical analysis, and CFD modeling for resilient designs. Don’t risk obsolescence—contact PPS today for expert consultations!

FEA Failure Analysis: Reduce Costs & Prevent Design Failures

Master finite element analysis failure theories to avoid costly overruns. Learn von Mises, Tresca, and Coulomb-Mohr to optimize designs and reduce prototype costs.”

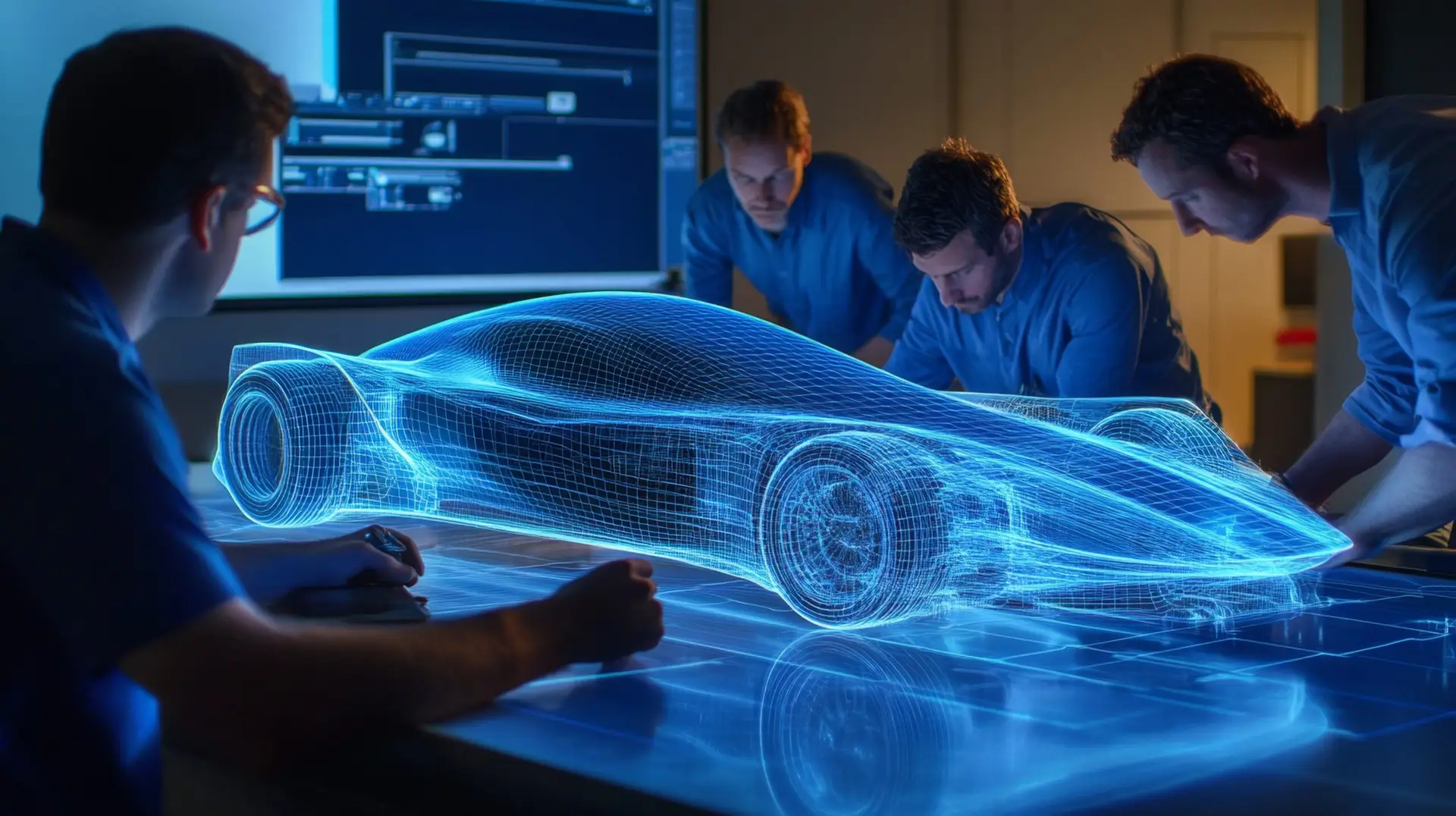

FEA Results: Static Theories of Failure – Part 1 of 8

In the field of mechanical engineering, interpreting finite element analysis (FEA) results is vital to prevent costly failures. This guide explores advanced analysis tools and the importance of selecting the right failure theories. By understanding design allowable practices and various failure modes, engineers can enhance product safety and reliability. Learn how to streamline your design process, reduce risks, and achieve faster project timelines. Join us as we discuss strategies for building resilient structures that meet real-world demands.

Simulation Modeling Cuts Costs by 73% & Speeds Up Design

High prototype costs slowing you down? PPS’s simulation modeling slashes costs by 73% and accelerates product cycles by 54%. Stay competitive—get your assessment!