PLM Revolution: 6 Key Takeaways for Manufacturers

Explore the PLM revolution’s impact on manufacturing with insights on data integration, smart factories, digital twins, and CFD analysis. Learn how to enhance efficiency, reduce cost, and gain a competitive advantage through machine learning, real-time data, and product design and development using data analysis tools.

Deliberate Pace Wins in Tech-Driven Worlds

Avoid digital transformation pitfalls by adopting a deliberate pace with industrial automation and simulation modeling. This strategy reduces costs in the long term, optimizes manufacturing processes, and builds competitive advantage through data analysis tools and renewable energy integration.

Why Choose PPS for Industry 4.0 Transformation Now?

In 2025, manufacturing faces talent shortages and rapid Industry 4.0 changes. Pure Prime Solutions offers digital twin consulting, simulation modeling, and sustainable strategies to reduce costs and boost efficiency. Overcome challenges and gain a competitive edge with PPS’s

Go Slow to Go Fast: Winning in a Tech-Driven World

Discover how going slow accelerates success in industrial automation and renewable energy. Explore smart factory strategies, digital twins, and value chain optimization for competitive advantage.

Renewable energy expertise: Accelerate 54%, cut costs 73%

Facing renewable energy delays and high costs? PPS’s sustainable engineering cuts costs by 73%, accelerates timelines by 54%, and ensures compliance. Schedule your free assessment!

Industry 4.0 Solutions for Smart Manufacturing | PPS

Manufacturers face mounting pressure to cut costs while boosting output. Industry 4.0 isn’t optional anymore—it’s essential. Companies failing to adopt digital manufacturing risk losing 15% market share annually. PPS delivers proven solutions: our Industry 4.0 optimization framework cuts manufacturing costs by 40% and increases production output by 35%, as validated by leading manufacturers. Using digital twin technology, simulation modeling, and smart factory strategies, we eliminate inefficiencies before they drain your budget. Our clients reduce development cycles by 54% and prototyping costs by 51%. The competitive advantage is immediate. Don’t fall behind—manufacturers adopting Industry 4.0 today capture tomorrow’s market. Your competitors are already moving. Request a free consultation with our engineering experts today.

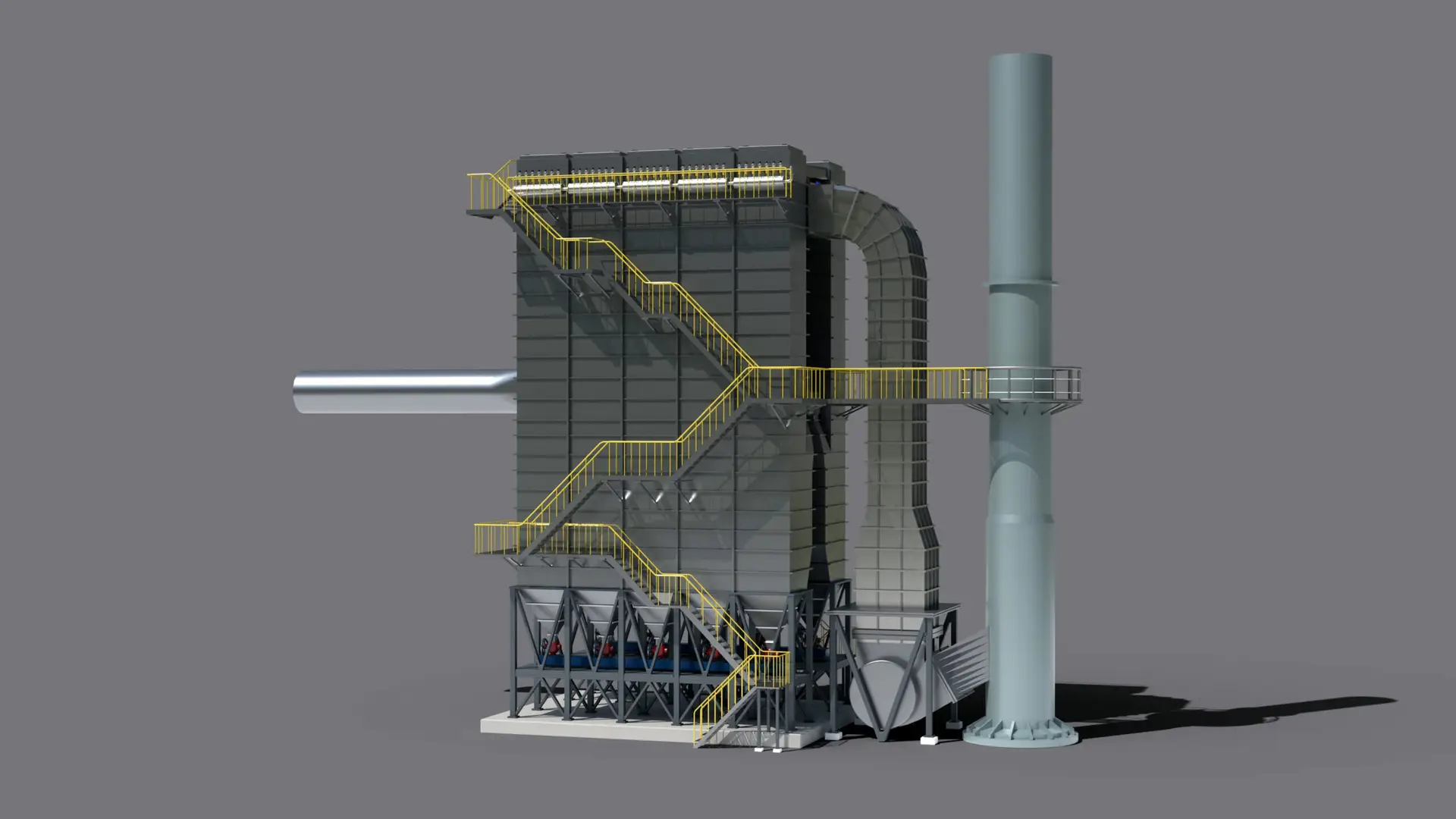

Turn Air Pollution Challenges into Opportunities

Struggling with air quality standards? PPS’s air pollution control solutions cut costs by 73%, speed timelines by 54%, and ensure compliance. Claim your free assessment!

Boost Automotive Manufacturing: Slash Costs by 73% Today

Struggling in automotive manufacturing? PPS’s Industry 4.0 solutions cut costs by 73%, boost efficiency, and speed production. Claim your free efficiency audit!

Aerospace Engineering: Reduce Costs by 73%, Speed Up 54%

Aerospace engineering projects cost too much and take too long. PPS cuts design costs by 73%, accelerates development by 54%, and validates designs digitally.”

Sustainable Cement Manufacturing Can Save You Up To 73%

Struggling with high energy costs and strict regulations? PPS optimizes cement plants, cutting costs by 73%, boosting efficiency, and achieving sustainability.