Key Points

- Minimizes costs by replacing physical prototypes with virtual simulations, saving up to 76% in prototyping expenses.

- Speeds up time to market with rapid iterations, achieving up to 75% reduction in development time.

- Improves product quality through accurate predictions under extreme conditions, meeting 90% of quality targets.

- Promotes innovation and collaboration across teams, leading to 30% faster innovation cycles.

Transforming Engineering: The Simulation Revolution

In the competitive world of engineering, traditional product development often struggles with high costs and lengthy timelines. Simulation-driven product development (SDPD) changes this by using advanced simulation software to create virtual models, allowing teams to test and refine designs digitally. This method integrates simulation modeling and analysis early, helping identify issues before they become expensive problems.

Companies adopting SDPD see significant gains in efficiency and sustainability. For instance, it reduces reliance on physical prototypes, cutting waste and aligning with eco-friendly practices. As global markets demand faster innovation, understanding SDPD’s role is crucial for staying ahead.

Whether in automotive or aerospace, SDPD empowers engineers to explore complex geometries and material properties virtually. It fosters a proactive approach to design challenges. Embracing these tools unlocks new levels of precision and creativity.

Understanding Product Development Fundamentals

Product development involves a series of steps from concept to launch, solving real-world issues with innovative solutions. Stages like prototyping, testing, and production require careful coordination to succeed. Precision is key to avoiding revisions that drive up costs.

Traditional approaches create dependencies that slow progress and introduce errors. Material limitations and human factors add further complications. Shifting to digital methods resolves these by enabling virtual workflows.

Simulation modeling and analysis are central, allowing testing without physical builds. This optimizes resources and reduces risks. The result is more dependable products.

Modelling and simulation enhance every phase, providing insights into system behavior. It supports engineering design by predicting outcomes accurately. Teams gain confidence in their decisions.

Exploring Simulation-Driven Methodologies

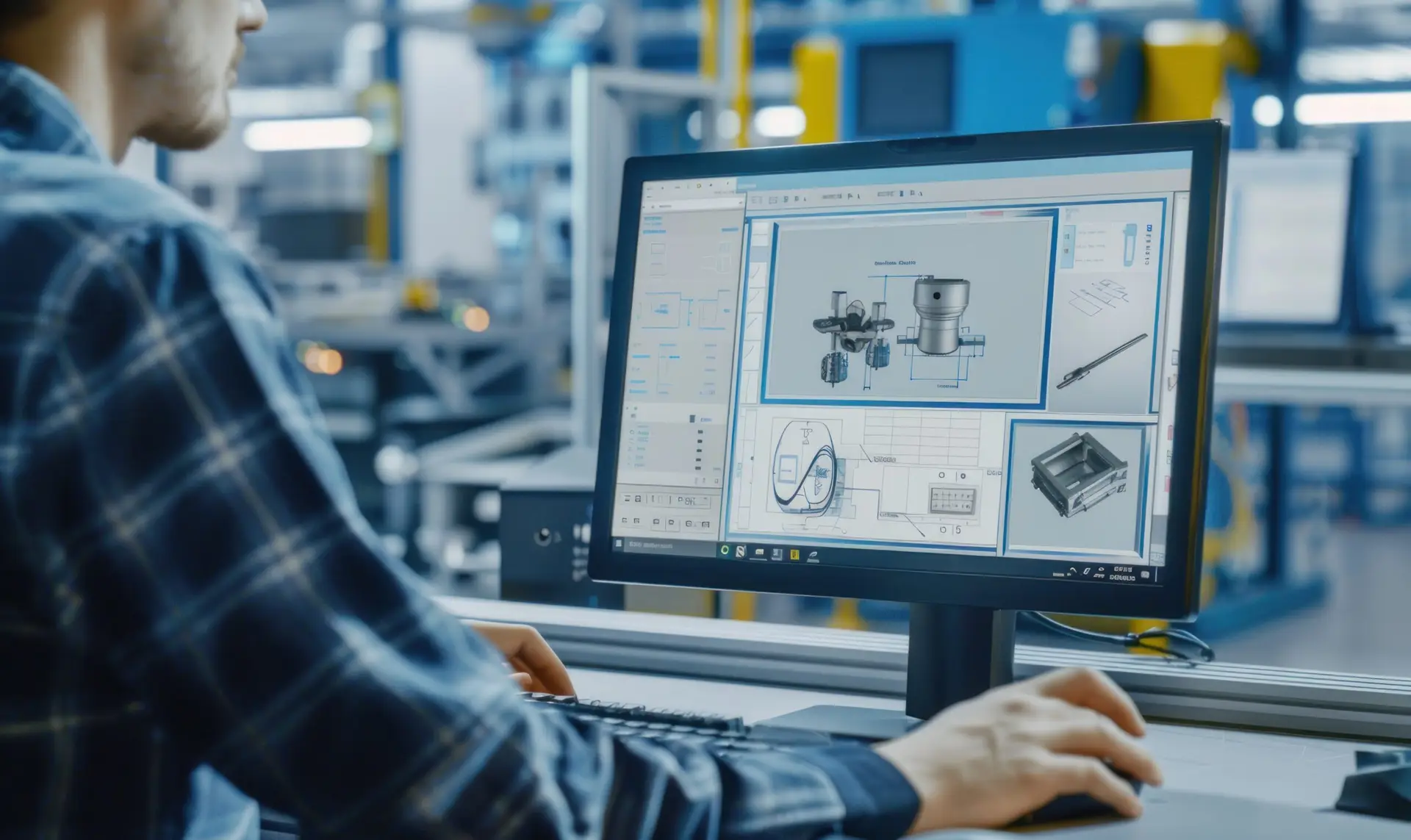

SDPD employs computational tools throughout, digitizing processes for greater accuracy. CAD, CAE, and DFM form the foundation for effective designs. These integrate to streamline assembly and manufacturing.

Early validation through simulations spots flaws quickly. Finite element analysis (FEA) and CFD analysis services evaluate structures and fluids. Designs are tested against real stresses virtually.

Process model simulation software models full systems precisely. Systems engineering modeling and simulation combine inputs from various fields. Innovation accelerates with maintained standards.

Numerical methods underpin these tools, enabling complex calculations. Post-processing interprets results for actionable insights. This approach refines designs iteratively.

Achieving Cost Savings and Efficiency

Cost reductions are a primary benefit, as virtual testing eliminates pricey prototypes. In industries like aerospace, CFD modeling replaces experiments, conserving resources. Firms save significantly on materials and labor.

Material modeling in finite element analysis predicts behaviors without waste. Finite element modeling and simulation with Ansys Workbench handles thermal and mechanical analysis efficiently. Budgets stay controlled through these technologies.

Unnecessary iterations decrease, directing focus to promising designs. Efficiency improves financial outcomes. Adopters report healthier bottom lines. According to Aberdeen research, best-in-class companies reduce physical prototypes by 76%.

This virtual shift cuts overall expenses. Long-term savings accumulate rapidly.

Shortening Time to Market

SDPD accelerates development by answering questions quickly and accurately. Sequential validation in traditional methods causes delays. Simulations handle multiple scenarios simultaneously. CFD analysis provides fast fluid insights.

Finite element analysis for design engineers allows quick modifications. Products reach markets sooner than competitors. Flow simulation forecasts performance in diverse conditions. Mechanical engineering design gains from predictive power.

Revenue starts flowing earlier. Studies show a 75% reduction in development time for top performers. Rapid cycles meet market demands. Competitive edges sharpen.

Boosting Product Quality and Reliability

Quality improves as simulations test designs in extreme, unreachable lab conditions. Virtual refinements optimize performance. Thermal analysis evaluates heat effects precisely. The finite element method (FEM) adds reliability through detailed predictions.

Ansys tools handle nonlinear complexities. Products become more durable. Proactive failure management reduces recalls. Customer satisfaction increases.

Quality sets brands apart. A 90% quality target achievement rate is typical among industry leaders. Accurate modeling ensures reliability. Excellence becomes standard.

Reducing Waste and Promoting Sustainability

Redesign waste stems from early gaps in knowledge. Virtual iterations evaluate options efficiently. CFD simulation uncovers optimal designs promptly. Sustainability explores without physical trials. Simulation software predicts accurately, minimizing resources.

Material and energy waste drops. Complex geometries are handled digitally. Modeling approaches enhance eco-practices. Global goals are supported.

Boeing’s case shows 25% waste reduction, saving billions annually. Virtual methods align with green initiatives. Efficiency meets environmental needs.

Fostering Team Collaboration and Innovation

Interdisciplinary work thrives with simulation, enhancing creativity. Experts integrate seamlessly via shared platforms. CFD modeling connects fluid and structural teams. Data tools aid understanding across groups.

Synergy produces novel solutions. Collective achievements multiply. Global expertise is accessible. Real-time platforms enable contributions. Breakthroughs emerge from collaboration.

72% of manufacturers report faster innovation. Team dynamics improve. Creativity flourishes in connected environments.

Gaining Strategic Business Oversight

Simulations extend beyond products to supply chains. Managers forecast revenues accurately. CFD analysis services guide decisions. Holistic views predict success. Risks are mitigated effectively. Resilience strengthens.

Knowledge expands globally. Independent ideas diversify innovation. Horizons broaden—mathematically model processes for precise insights. System design optimizes operations. Strategic advantages accumulate.

Real-World Applications: Case Studies

Siemens utilized simulation for gas turbines, reducing time-to-market by 35%. Reliability increased 30%, saving $100 million over five years. This demonstrates cost and efficiency gains.

Ford reduced prototype costs by 40% using FEA and CFD—early flaw detection streamlined development. Innovation accelerated significantly.

LIXIL achieved 75-85% design confidence using Ansys. Time-to-market shortened notably. Complex products were tested virtually.

TEN TECH reduced simulation times from weeks to clicks. Challenges are addressed faster. Productivity soared in consulting.

Conclusions

Simulation-driven product development revolutionizes engineering with superior cost, time, and quality benefits. Tools like finite element analysis FEA and computational fluid dynamics CFD enable virtual exploration of material properties and complex geometries. This pivot from physical prototypes to digital models ensures sustainable, innovative outcomes in dynamic industries.

Early adopters avoid traditional pitfalls, gaining an edge in competitiveness. Investments in modeling, including Ansys and process software, yield long-term returns. Transformative gains outweigh transition challenges.

SDPD ultimately equips leaders to deliver outstanding products. It’s essential for forward progress. Embrace it to reshape your strategies.